Welding Case Study

Welding Assembly

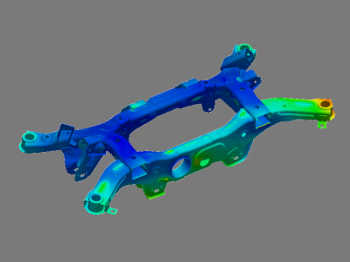

Welding of thick/thin-walled chassis and body-frame parts

Automotive OEM and selected suppliers, railway and aerospace industry.

Thick/thin-walled chassis and body structures.

- Usually, parts are assembled by welding process. Car chassis components have 5 to 100 welding joints. The trend is always to reduce the number of welding joints.

- Reduction of fuel consumption leads to usage of lightweight material. Strength, plasticity, corrosion-resistance and weldability leads to aluminum material.

- Aluminum needs a big power input to be welded properly, on the other hand, the distortions are higher than steel. The goal of simulation is to predict and minimize the distortions by optimization of all components of the welding assembly process.

- If the concern is high security for in service behavior, the interest is also the loss of mechanical properties and the residual stresses which give input for further fatigue and structure computations.

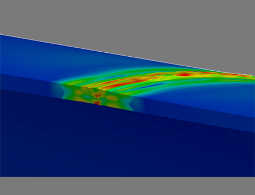

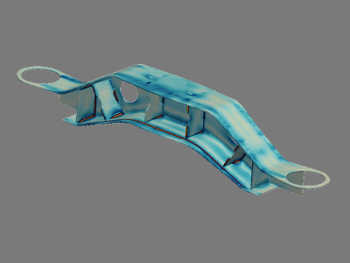

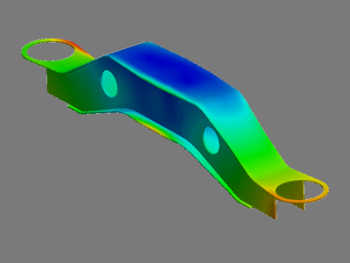

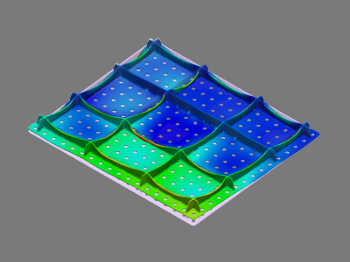

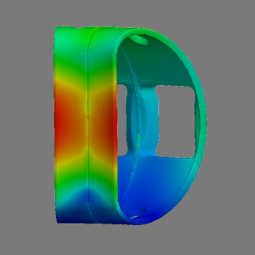

Temperature distribution

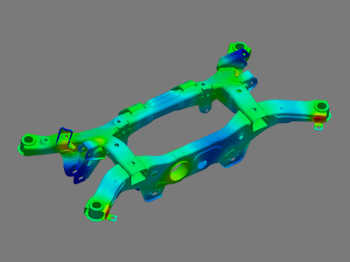

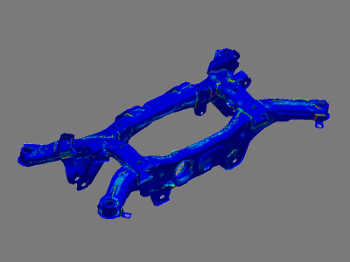

Residual stress after welding

Distortion after welding

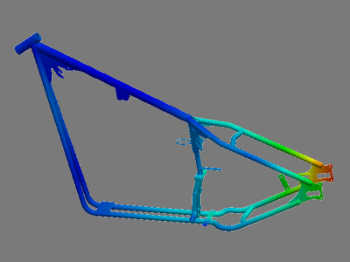

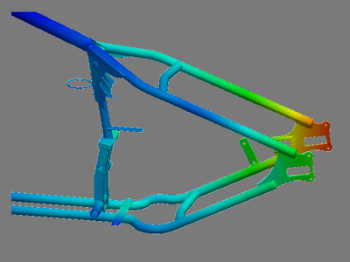

Motorcycle body frame

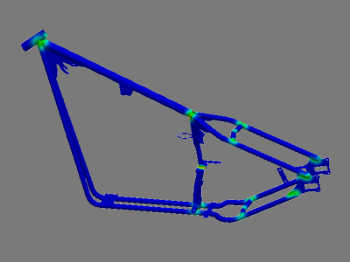

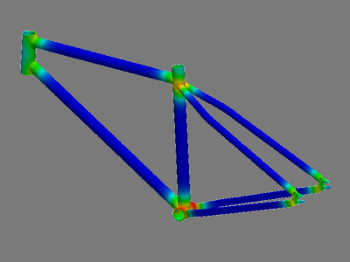

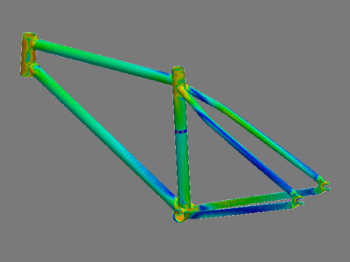

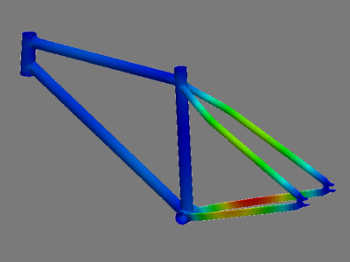

Bicycle body frame

Thin wall frame

- The objective of such simulations is generally to minimize distortion. The evaluation of the best clamping tool position is one task, next to process parameter optimization.

- Minimize in service failure: Fatigue life and crack risk prediction must take into account residual stresses and stress gradients due to welding. By optimizing all components of a welding repair process, risk factors could be reduced.

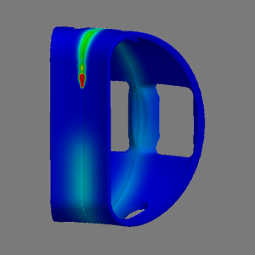

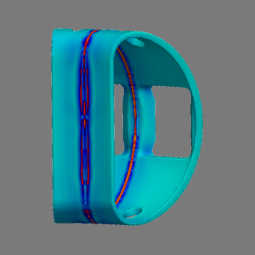

Residual stress after welding

Distortion after welding

Distortion after welding(enlarge)

Temperature distribution

Residual stress after welding

Distortion after welding

Welding Assembly

Welding of large structures for the railway industry

Railway and related thin/thick wall parts.

Welding Assembly of parts by multi-pass or single pass welding.

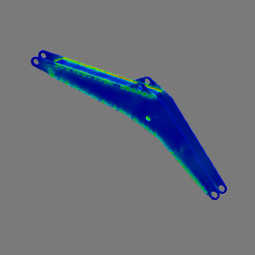

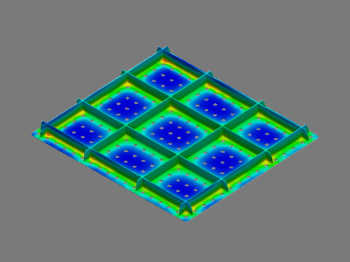

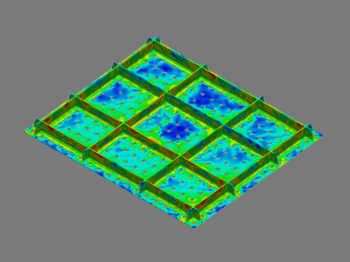

- The objective of simulations is generally to minimize distortion. Distortion repair takes 20% to 40% of the total manufacturing cost.

- In the industrial sectors, welded parts are often quite large and expensive. Prototyping and destructive measurement tests are often not acceptable. The numerical simulation is a powerful tool to reduce cost.

- Control residual stresses to minimize in service failure. Fatigue life and crack risk prediction must take into account residual stresses and stress gradients due to welding. By optimizing all components of a welding process, risk factors could be reduced.

Temperature distributio

Residual stress after welding

Distortion after welding, bogie frame

Welding Assembly

Welding of large structures for the heavy industry

Heavy industry

Ship building and building of construction machines.

Welding Assembly of parts by multi-pass or single pass welding

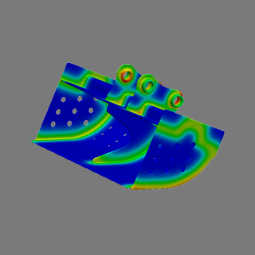

- The objective of simulations is generally to minimize distortion. Distortion repair takes 20% to 40% of the total manufacturing cost.

- In the industrial sectors, welded parts are often quite large and expensive. Prototyping and destructive measurement tests are often not acceptable. The numerical simulation is a powerful tool to reduce cost.

- Control residual stresses to minimize in service failure. Fatigue life and crack risk prediction must take into account residual stresses and stress gradients due to welding. By optimizing all components of a welding process, risk factors could be reduced.

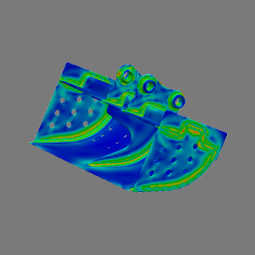

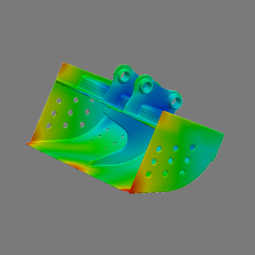

Temperature distribution

Residual stress after welding

Distortion after welding

Ship building and building of construction machines.

Welding Assembly of parts by multi-pass or single pass welding.

- The objective of simulations is generally to minimize distortion. Distortion repair takes 20% to 40% of the total manufacturing cost.

- In the industrial sectors, welded parts are often quite large and expensive. Prototyping and destructive measurement tests are often not acceptable. The numerical simulation is a powerful tool to reduce cost.

- Control residual stresses to minimize in service failure. Fatigue life and crack risk prediction must take into account residual stresses and stress gradients due to welding. By optimizing all components of a welding process, risk factors could be reduced.

Temperature distribution

Residual stress after welding

Distortion after welding

Welding Assembly

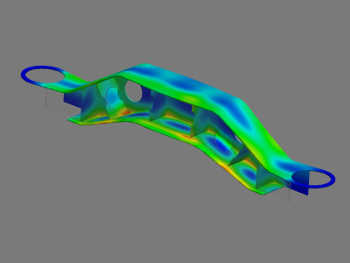

Residual stress control and improvement of fatigue performance

Dynamically loaded frame and suspension system components

Dynamically loaded engine and transmission components

Energy machine components

Aero-engine manufacturers

Welding of turbine components

- Control distortions: this kind part components must have very limited distortions to ensure a good in service behavior. Welding is the cheapest way of joining, but produces distortion. By numerical of simulation, the distortion caused by welding could be controlled.

- Control residual stresses to minimize in service failure: The reliability is of major concern. Fatigue life and crack risk prediction must take into account residual stresses and stress gradients due to welding. By optimizing all components of a welding process, risk factors could be decreased.

Temperature distribution

Residual stress after welding

Distortion after welding, Part size: 45m x 68m x 28m, Total 22 PCS

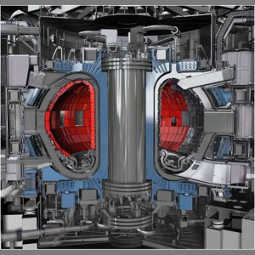

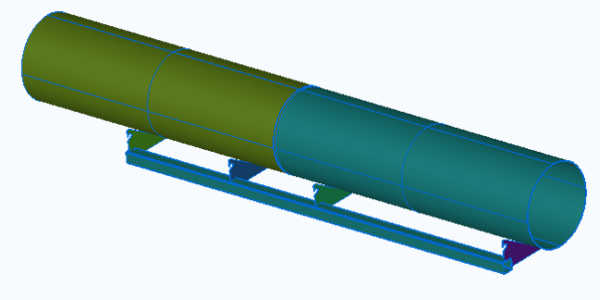

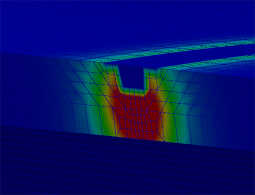

Multipass welding

Nuclear and general energy industry, ship building, vessel building and building of construction machines.

- Minimize in service failure: The reliability is of major concern. Fatigue life and crack risk prediction must take into account residual stresses and stress gradients due to welding. By optimizing all components of a welding repair process, risk factors could be decreased.

- In the named industrial sectors, welded parts are often quite large and expensive. Prototyping and destructive measurement tests are often not acceptable. The numerical simulation is a powerful mean to reduce cost.

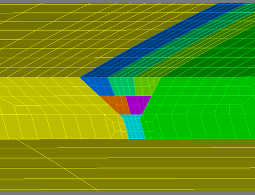

Pipe: multi-pass welding

multi-pass weld layout

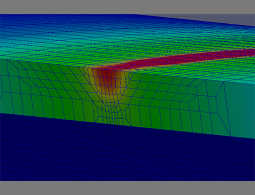

Temperature: 1st pass weld

Temperature last pass weld